2017-12-11T16:45:00.0000000+00:00

December 11, 2017

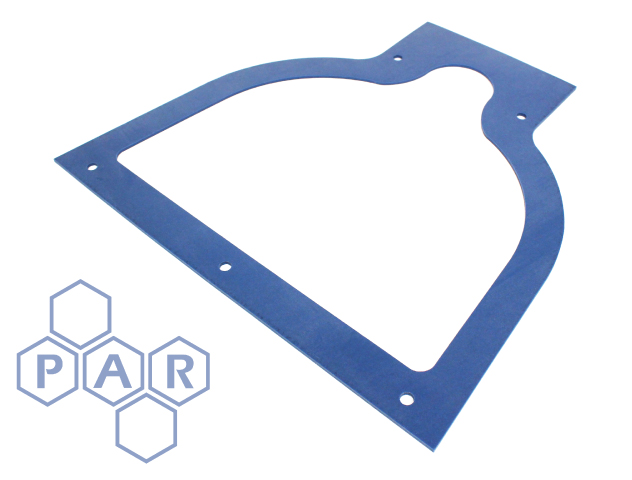

Metal detectable silicone rubber gaskets contain additives which make them visible to metal detector scanning equipment. This ensures that any rubber contamination within the product can quickly and easily be identified. Silicone also displays excellent heat resistance and is FDA approved for use in food contact applications.

The Project

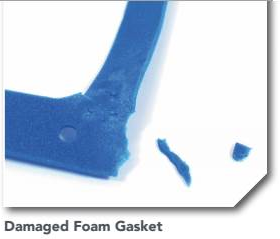

A food manufacturer had an issue with an original gasket whereby the gasket, manufactured out of a blue foam, had broken down over time and contaminated some of their product. This resulted in the scrappage of a substantial amount of product as the location of the contamination couldn’t be determined.

The Solution

PAR suggested the replacement of all foam gaskets with metal detectable silicone. By obtaining a sample of the original gasket we were able to trace the exact profile using our in-house digitising facilities. This was then precision cut at our Preston branch using our CNC profile cutting capabilities. Replacing the original foam with metal detectable silicone ensures any future contamination is quickly found and removed from the production line.

Key Features

• Visible to metal detector scanners.

• FDA approved material.

• Highly visible blue colour.

• Excellent heat resistance.

You can find out more about our range of metal detectable products by clicking here.