Gaskets can come in various shapes and sizes. We have put together a guide to help you measure some of the most common shaped gaskets correctly. Please follow the methods below to help you successfully measure a gasket.

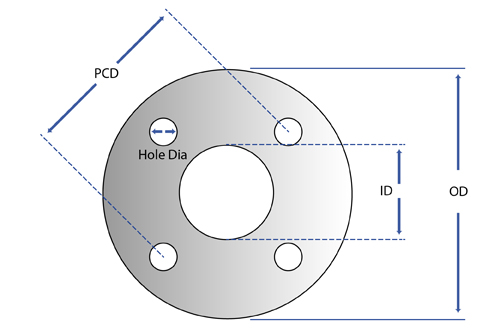

Measuring Flange Gaskets

Method 1: The PCD (Pitch Circle Diameter)

Flange gaskets are also referred to as full face gaskets and contain bolt holes on the face of the gasket. If you use this type of gasket then the PCD method will help you measure your gasket correctly. The PCD is the measurement between the centres of opposite holes. This can be measured with a tape measure from the inside of one hole to the outside of the other (as per the image above), providing the hole diameters are equal. It would also be useful to make note of the gasket thickness to ensure you know the complete dimensions required.

Method 2: The IBC (Inner Bolt Circle) Gasket

Often referred to as ring gaskets, inner bolt circle gaskets only costist of an outside diameter and an inside diameter (OD and ID). You can correctly measure this type of gasket by placing a tape measure (edge to edge) over the gasket face and taking note of the diameters accordingly. It's also advisable to measure the thickness of the gasket so you are able to provide complete dimensions.

Flange Gasket Tables - Please follow the link to view all standard flange gasket tables.

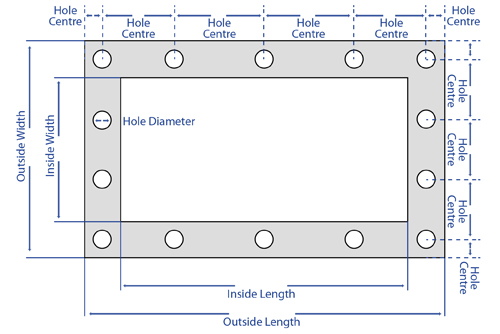

Measuring Picture Frame Gaskets

Usually square or rectangular in shape, picture frame gaskets will require both outside and inside measurements (which can be achieved with a tape measure). These types of gaskets will likely have bolt holes around the frame and often of consistant diameter and spacing (although this may not always be the case, so it is best to check). The above image provides full details on all measurements required for picture frame gaskets.

If you are having difficulty measuring any of your gaskets correctly, please contact PAR Group to discuss the options available. This could either be further advice on how to measure them yourself, sending a PAR representitive to measure these for you, or sending us a sample to measure from our sales offices.

Further Things to Consider When Measuring Gaskets

To enable us to quote for your gasket requirements, please provide the following information:

Quantity Required

Application:

- What are you trying to seal?

Size Details:

- Standard flange type.

- Dimensions from the drawing above (including the number of holes & material thickness).

- A drawing if non-standard.

Material:

- Product being conveyed.

- Temperature range.

- What is the gasket coming into contact with? (i.e. chemical, acids, solvents etc).

- Pressure rating required.

- Is the gasket for internal or external pipework. Other relevant environmental conditions.