Since 2013, an astonishing 18% of product recalls in the food industry were caused by physical contamination of products1.

Preventing contaminated food reaching the consumer is a stressful, expensive process; requiring x-ray scanning, along with the potential disposal of high volume product. Consequentially, if the contaminant is not located in time, this could lead to additional costs removing the product from the market, litigation risk, reduction of sales and most importantly, brand damage.

PAR Group have developed a product to help prevent product contamination and reduce production downtime during the packaging process of snack foods. Introducing, the Versa-Chute®.

Versa-chute® is a food safe, flexible, abrasion resistant chute designed for the transfer and sorting of dry foodstuffs, grain, grit, powders, wood shavings, dust and other abrasive materials. Manufactured from a very durable, clear thermoplastic polyurethane with a fully sealed and welded seam, all our Versa-chute® products are bespoke manufactured to your specific requirements.

The Problem with Rigid Plastic Chutes

Packaging machines are typically supplied with moulded, rigid plastic chutes as standard and alternative replacement parts can be fabricated and welded. A problem with any form of rigid plastic is that there is high risk of cracking, potentially causing product contamination and furthermore, increasing the risk of downtime while your chute is replaced, often at a high cost.

Above: A Cracked, rigid plastic chute.

Our Customers are Choosing Versa-Chute®

A major UK based snack food manufacturer had an issue with their rigid plastic chutes becoming cracked and worn very quickly causing several issues, predominantly the potential risk of contaminated product. Their rigid chutes also became cloudy as they wore (caused by the abrasive nature of the product) which made it difficult to see the product as it was being transferred.

PAR Group developed the Versa-chute®; a flexible, tough and durable product for the transfer and sorting of dry foodstuffs and other abrasives. For this particular project, we were able to take a broken sample away which was then measured and drawn. We then cut the material required using our CNC profile cutting capabilities before welding it into the exact shape required to maintain product flow.

Our Versa-chute® provided a superior solution for our customer as the material does not crack, is much more wear resistant, and can be installed without dismantling the packaging machinery due to its flexibility. It also provided a cost saving as Versa-chute®’s require replacing less frequently than rigid plastic counterparts.

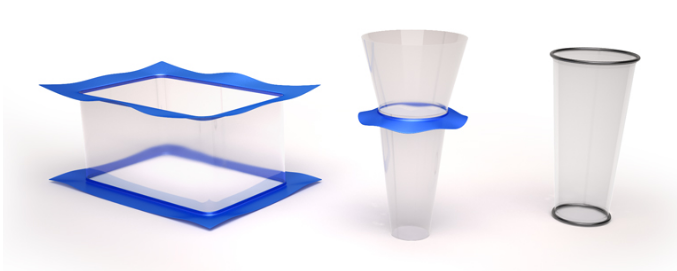

Above: The almost unbreakable Versa-chute® - Manufactured by PAR Group.

In a recent survey, we asked a selection of major UK food manufacturers whether they have ever damaged their 3mm thick Versa-chute® through cleaning or handling. They all reported no damage, some of which following years of use.

The video below shows the durability, impact resistance and strength of our Versa-chute®.

Key Features

- Tough, durable and extremely flexible.

- Very abrasion resistant with exceptional tear strength.

- Food approved materials.

- Reduces product contamination risk.

- Manufactured wholly in-house.

- Quick and easy to remove or replace from the packaging machine.

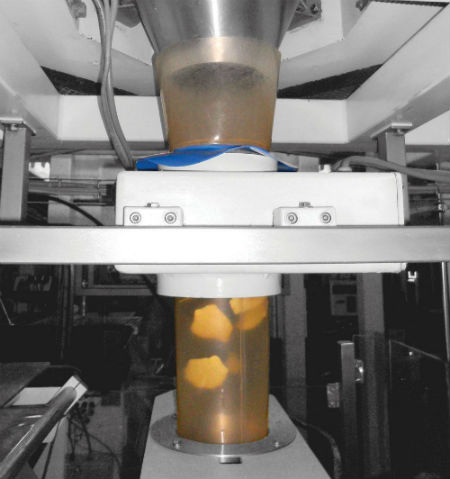

Above: Our Versa-chute® in situ.

Many manufacturers around the world have turned to the Versa-chute®. If this sounds like a product that would benefit your production line, you can find out more about our Versa-chute® by clicking here.

1Food Standards Association: Review of Food Withdrawal and Recall Process (2017).

If you found this article useful, why not share it on Linkedin by clicking the button below;