When using chemicals, engineers have faced mounting pressure over the years to adhere to EU regulations such as REACH (Registration, Evaluation, Authorisation & Restriction of Chemicals) along with pressure from the Environment Agency to control risks to human health and the environment.

Part of this regulation includes the prevention of chemical or hazardous leaks, whether through storage or fluid transfer.

Failing to meet these standards can lead to heavy fines. In 2017, it was reported that a well-known UK water authority were fined £45,000 for failing to contain a leak. They were also ordered to pay £24,762.56 to the Environment Agency as well as a victim surcharge of £120.

Prior to this, in 2016, a seperate UK water authority were fined a whopping £380,000, along with £23,092.64 costs for a similar leak into a fresh water stream.

Although the current means of prevention have been around for many years, more and more organisations are now stepping up to meet the standards set out by governing bodies to protect people and the environment.

One such prevention method is a dual containment hose.

What Is A Dual-Containment Hose?

A dual containment hose, also referred to as double walled tubing can be defined as a product where the primary transfer hose is supplied complete with an external tubing layer. The purpose of the external tubing is to help prevent hazardous matter escaping should the inner hose become breached. Breaches could occur due to instances where the inner hose becomes damaged due to the elements, chemical corrosion, or even impact.

It’s not just for chemicals; a hazardous material can be defined as a substance that is potentially harmful to a person or the environment, and can include chemicals, oil, petrochemicals and also slurry.

Should a leak occur, the chemical or hazardous waste is caught and contained within the outer hose, enabling it to be removed in a timely manner to prevent contamination.

The Potential Dangers of Single Containment Hoses

There are plenty of potential dangers when conveying chemicals or hazardous waste. Dual containment hoses help protect against:

• Uncontrolled mixing of incompatible chemicals.

• Chemicals or hazardous waste being released into sewers or even potable (clean) water.

• Environmental contamination.

• Injury to personnel through contact with harmful chemicals or liquids.

• Chemical damage to plant and equipment.

Chemical Compatibility

To help prevent chemical or hazardous waste leaks and spillages, both the inner hose and outer tubing material are vital in your dual containment hose choice.

A key requirement for inner hoses is the need for chemical resistance, whilst remaining flexible and strong. Some of the most suitable materials to meet this criteria are Polyester, PVC, Low Density Polyethylene (LDPE) or PTFE.

Outer tubes are manufactured from either PVC or Polyurethane to provide the layer of additional protection.

Depending on your application, some hoses may be more suitable than others:

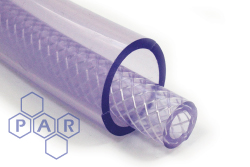

PVC (Braided) - 6101

PVC Dual Containment hoses are manufactured with a high tensile braided polyester reinforcing yarn for additional strength. These hoses are light-weight and flexible, whilst providing excellent protection from corrosion, abrasion and many industrial chemicals.

Temperature Range: -20°C to +65°C.

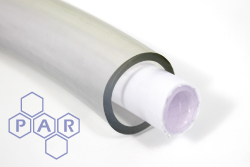

EVA LDPE - 6718

Reinforced with a Polyester yarn in the inner hose, EVA is a WRAS approved material making it a popular material for use with cold water connections, chemical lines and some liquid foodstuffs. EVA hoses are lightweight, flexible and have excellent chemical resistance properties.

Temperature Range: -20°C to +85°C.

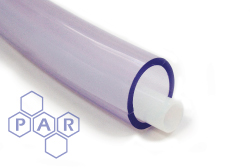

PTFE - 6712

This material has excellent chemical and temperature resistance making it a popular choice for the transportation of viscous media which can cause blockage. PTFE tubing is commonly used for conveying harsh chemicals.

Temperature Range: -70°C to +260°C.

If you would like to see how these hoses perform with certain chemicals, you can view the chemical resistance data by clicking here.

Other Ways to Stay Protected

Containment units (also known as catch-pots) can be incorporated into your application and are commonly found in the water treatment and chemical industry to help contain chemical leaks from hose and tubing. In dual containment hose applications, containment units are designed to be fitted around the outside of the inner carrier hose where a connection is required. This helps to quickly identify and contain any leaks from the joint. Containment units can also be used as a break in the outer containment tube with the inner tube remaining unbroken. This can provide a leak detection point.

PAR Group can manufacture bespoke containment units from a range of clear plastics and can be supplied curved or straight with a removable top if required. Pipe fittings and chemical resistant seals can also be incorporated if required.

If you would like to read more about containment units, please take a look at our containment units page.

Finally, if you found this article interesting, why not share it on LinkedIn by clicking the button below.